Stock Adjustments

Stock adjustments correct inventory quantities when the recorded stock does not match what is physically on the shelf. Every adjustment is tracked with a reason code and creates an audit trail for accountability.

When Stock Is Adjusted

Stock quantities change through several mechanisms in Brother POS:

Manual Methods

- Editing the product -- On the product edit page, you can directly change the

current_stockvalue and save. This is the primary way to manually adjust stock. - Bulk stock adjustment API -- Programmatic stock adjustments can be made through the API.

Automatic Methods (System-Generated)

Stock is adjusted automatically by the system in these scenarios:

- Sales -- Stock is deducted when a sale is completed on the POS.

- Voided sales -- Stock is restored when a sale is voided.

- Returns -- Stock is added back when a return is processed.

- Purchase order receiving -- Stock increases when inventory is received against a PO. See Purchase Orders.

- Stock transfers -- Stock is deducted at the source store and added at the destination store. See Stock Transfers.

Brother POS does not have a separate "Stock Adjustments" page in the admin navigation. Stock is adjusted by editing the product directly, through sales and returns, PO receiving, stock transfers, or via the API.

Adjustment Types

Adjustment types categorize why a stock change was made. They are critical for accurate reporting and compliance. These types are set programmatically when adjustments occur, not selected by users through a form:

| Adjustment Type | Description |

|---|---|

| Count | A physical count revealed a discrepancy between actual and recorded stock. |

| Spoilage | Product has spoiled, expired, or degraded and cannot be sold. |

| Damage | Product was physically damaged and cannot be sold. |

| Moisture Loss | Weight-based product lost weight due to moisture evaporation (cannabis-specific). |

| Reweigh | A batch of weight-based products was reweighed and the total differs from the recorded amount. |

System-Generated Adjustment Types

These types are created automatically by the system:

| Adjustment Type | Created When |

|---|---|

| Sale | A product is sold at the POS. |

| Voided Sale | A sale is voided and stock is restored. |

| Stock Received | Inventory is received against a purchase order. |

| Consignment Received | Consignment inventory is received. |

| Transfer In | Stock arrives from another store via a stock transfer. |

| Transfer Out | Stock is sent to another store via a stock transfer. |

Adjustment types drive your shrinkage reports and compliance records. When adjustments are made programmatically, ensure the most accurate type is provided.

For cannabis products, stock adjustments are included in compliance reports submitted to regulatory bodies (e.g., SLGA in Saskatchewan). Accurate reason codes and notes are essential for passing audits.

Adjusting Stock on a Product

To manually adjust a product's stock:

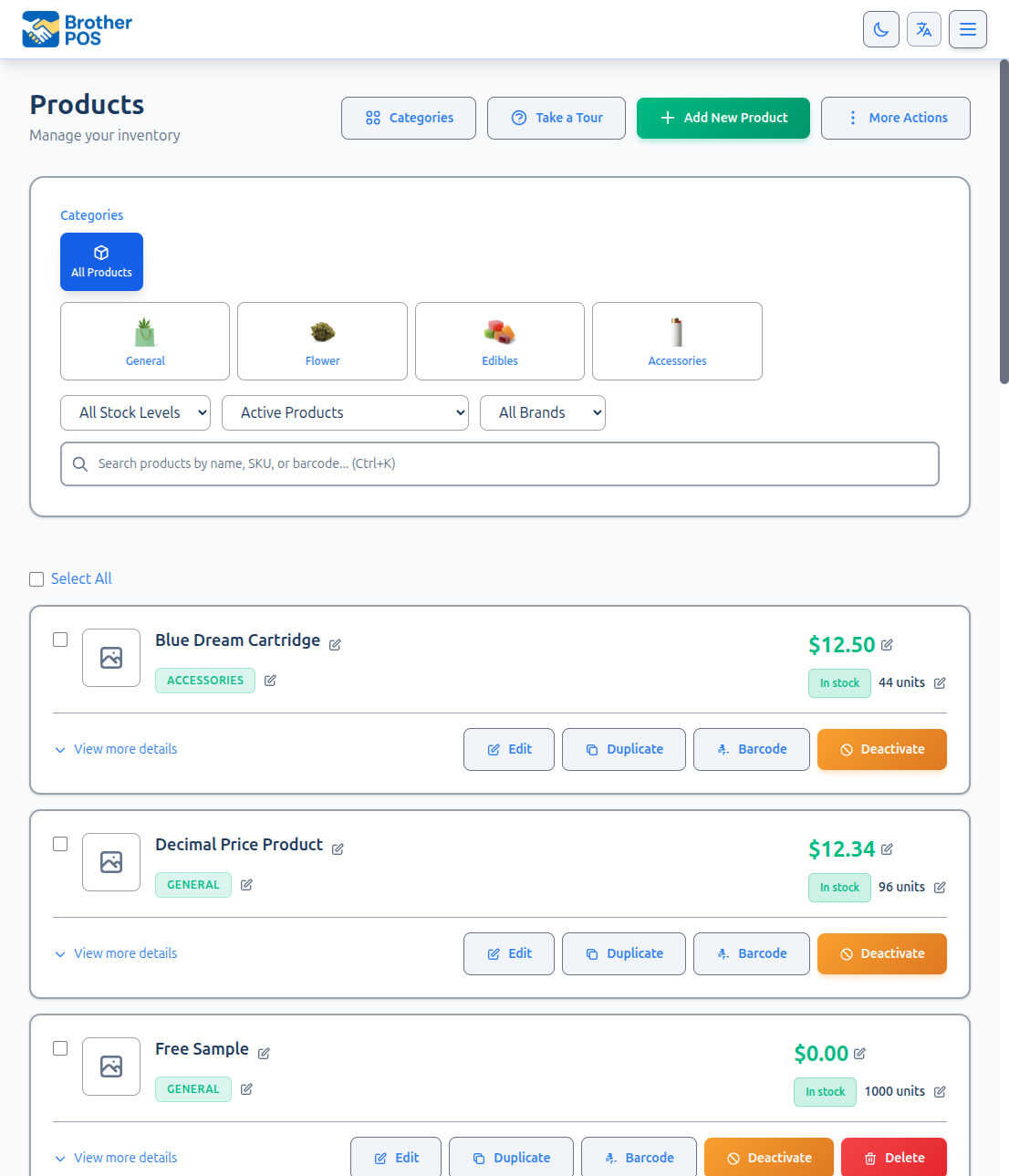

- Navigate to Products and click the product you want to adjust.

- On the product edit page, find the Current Stock field.

- Change the value to the correct quantity.

- Click Save.

For products with variations, adjust stock on each individual variation through the parent product's edit page.

Viewing Adjustment History

Stock adjustment history is viewable in Reports > Inventory Report with date filtering. This report shows stock changes across all products, including both manual and system-generated adjustments.

Audit Trail

Every stock change creates a permanent audit record that includes:

- Timestamp -- When the adjustment was made.

- User -- Who performed the adjustment (linked to their admin account).

- Product/Variation -- What was adjusted.

- Before/After -- Stock level before and after the change.

- Adjustment Type -- Why the change was made.

- Notes -- Any additional context provided.

Audit records cannot be edited or deleted. This ensures a complete, tamper-proof history of all inventory changes.

If your store is subject to regulatory audits, the stock adjustment audit trail is your primary evidence of inventory control practices.

Best Practices

- Count regularly. Perform physical counts weekly for high-value or high-turnover items, and monthly for the full catalog.

- Investigate discrepancies. Large or recurring discrepancies may indicate theft, receiving errors, or POS issues. Do not just adjust and move on.

- Restrict access. Only Admins and Managers can make stock adjustments. Cashiers cannot modify stock.

- Use purchase orders for receiving. Avoid manually adjusting stock when receiving supplier shipments. POs create a proper paper trail. See Purchase Orders.

What's Next?

- Purchase Orders -- Receive new inventory from suppliers.

- Stock Transfers -- Move stock between stores.

- Low Stock Alerts -- Get notified when stock runs low.

- Managing Products -- Return to the product list.