Stock Transfers

Stock transfers let you move inventory from one store to another within your Brother POS multi-store setup. This is useful for balancing stock across locations, fulfilling urgent needs at one store from another's surplus, or consolidating inventory.

Stock transfers require a multi-store (multi-tenant) deployment. If you operate a single store, this feature does not apply to your setup.

How Transfers Work

Stock transfers in Brother POS are immediate. When you submit a transfer, the system instantly:

- Deducts the transferred quantities from the source store's inventory.

- Adds the quantities to the destination store's inventory.

- Marks the transfer as Completed.

There is no approval or shipping step. This design is intentional -- in a multi-store deployment managed by the same owner, transfers are trusted operations that take effect right away.

Creating a Stock Transfer

Step 1: Initiate the Transfer

- Navigate to the Products page dropdown > Ordering & Transfers > Stock Transfers in the admin panel.

- Click New Transfer.

- The Source Store is automatically set to your current store and cannot be changed.

- Select the Destination Store — the store receiving the inventory.

Step 2: Add Items

- Click Add Item.

- Search for the product by name or SKU in the source store's catalog.

- If the product has variations, select the specific variation.

- Enter the Transfer Quantity — how many units to send.

- The current stock at the source store is shown for reference.

- Repeat for each product you want to transfer.

The system shows the current stock at the source store for each product. You cannot transfer more than what is available. If the stock level is low, consider whether the source store can afford to send these units.

Step 3: Add Notes

| Field | Required | Description |

|---|---|---|

| Transfer Number | Auto-generated | A unique identifier for this transfer (format: ST-YYYYMMDD-0001). |

| Notes | No | Reason for the transfer or special instructions. |

Step 4: Submit the Transfer

Click Submit Transfer. The transfer executes immediately:

- Source store stock is deducted. The transferred quantities are removed from the source store's inventory.

- Destination store stock is increased. The quantities are added to the destination store.

- If the destination store does not already carry a product included in the transfer, a matching product record is created automatically at the destination store using the source product's details.

- A stock adjustment record is created at both stores for audit purposes.

- The transfer status is set to Completed.

When a transfer includes a product the destination store does not currently carry, Brother POS first tries to match by SKU, then by name. If no match is found, it creates a new product record using the source product's details (name, SKU, price, category, etc.). Review these new products to ensure the pricing and categorization are appropriate for the destination store.

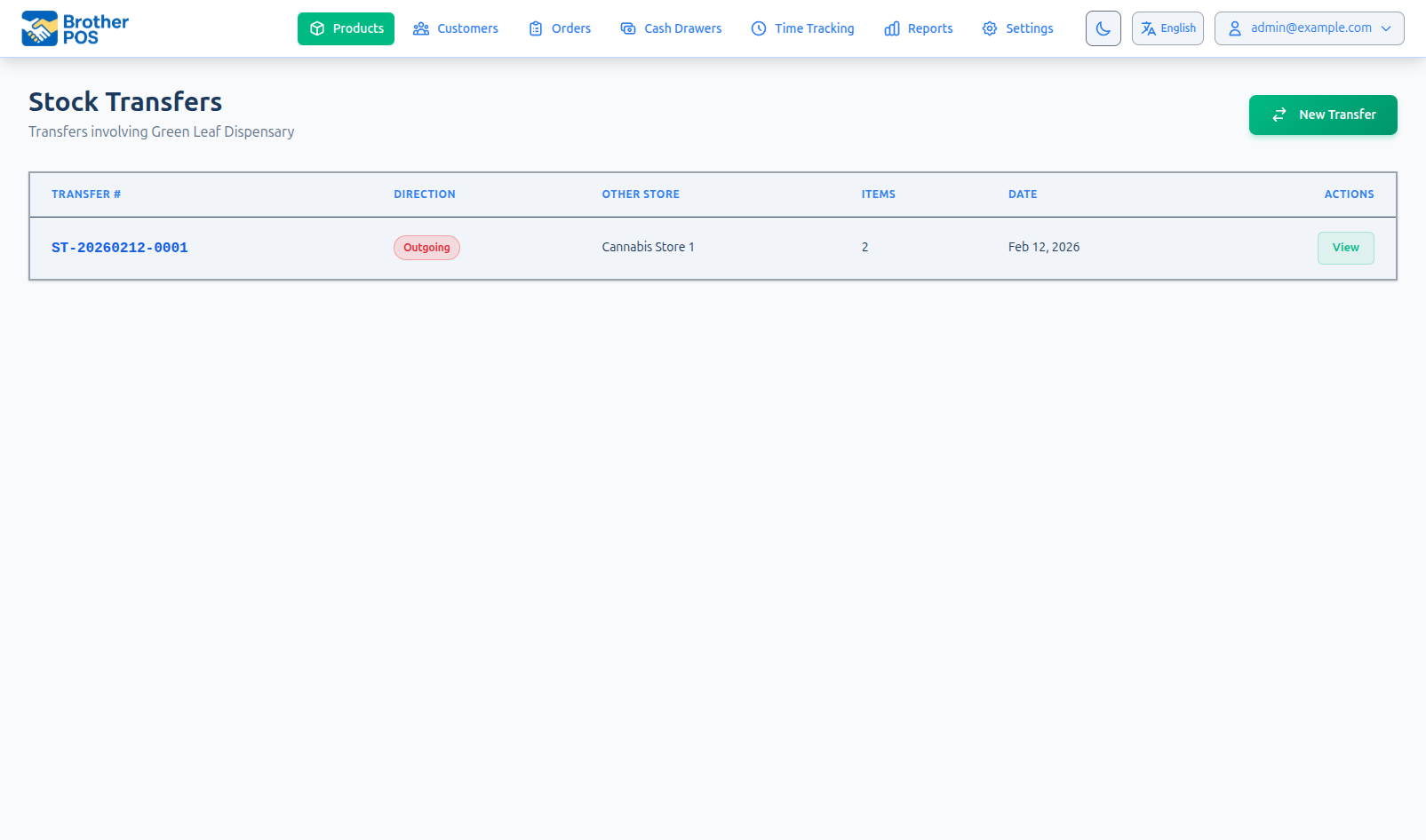

Viewing Transfer History

- Navigate to the Products page dropdown > Ordering & Transfers > Stock Transfers.

- The transfer list shows all transfers involving your store (both incoming and outgoing).

- Each transfer record includes:

- Transfer number and date.

- Source and destination stores.

- All line items with quantities.

- The user who initiated the transfer.

- Any notes.

Best Practices

- Document the reason. Always include notes explaining why the transfer is being made. This helps with future auditing and analysis.

- Verify stock before transferring. Check that the source store has enough stock. The system shows current stock for each product during transfer creation.

- Review new products. When transferring products the destination store has not carried before, review the auto-created product records to set appropriate local pricing and categories.

- Keep transfers manageable. Send multiple smaller transfers rather than one massive one. This makes it easier to track and audit.

- Coordinate physically. While the system records update instantly, you still need to physically move the products between locations.

What's Next?

- Stock Adjustments — Correct stock discrepancies from transfers.

- Purchase Orders — Order new inventory from suppliers instead of transferring.

- Low Stock Alerts — Identify which store needs stock before it runs out.

- Reservations — Understand how reserved stock interacts with transfers.