Low Stock Alerts

Low stock alerts help you identify products whose stock has fallen below a configured threshold. This gives you time to reorder from suppliers or transfer stock from another store before the product runs out completely.

How Low Stock Alerts Work

Brother POS calculates low stock products on-demand when the inventory report is loaded. When a product's current stock is at or below its low stock threshold, the product is flagged as "Low Stock" in the report.

Low stock status is calculated when you load the inventory report. There is no continuous background monitoring or notification system -- you must check the report to see which products are low.

Setting Low Stock Thresholds

Each product has its own low_stock_threshold field. The database default is 5. There is no store-wide configurable default -- set thresholds per product on the product edit page.

Per-Product Threshold

- Navigate to Products and click the product.

- On the product detail page, find the Low Stock Threshold field.

- Enter the threshold value (e.g.,

25for a fast-moving item). - Click Save.

Think about your typical reorder lead time. If it takes 3 days to receive a supplier shipment and you sell about 5 units per day of a product, a threshold of 15 gives you a comfortable buffer. Adjust based on your actual sales velocity and supplier reliability.

Per-Variation Threshold

If a product has variations, thresholds are set at the variation level:

- Navigate to the product detail page.

- In the Variations section, click Edit on the variation.

- Set the Low Stock Threshold for that variation.

- Click Save.

Each variation is tracked independently. A product might have its "1g" variation in low stock while the "3.5g" variation is well stocked. Both are flagged separately.

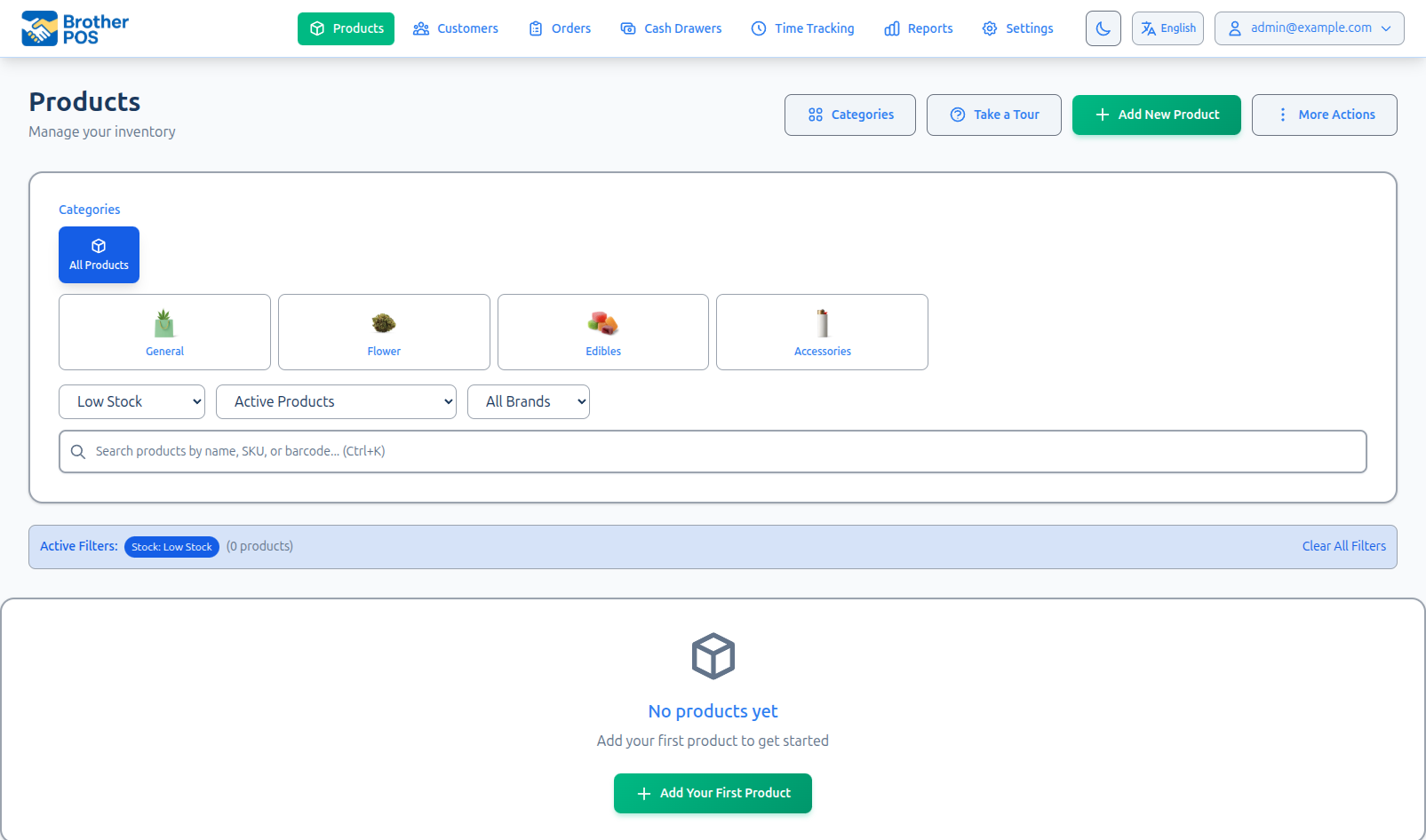

Viewing the Low Stock Report

The low stock report shows all products currently below their threshold.

- Navigate to Reports > Inventory in the admin panel.

- The report displays a table of flagged products:

| Column | Description |

|---|---|

| Product | Product name (and variation, if applicable). |

| SKU | The product's SKU. |

| Current Stock | How many units are physically on hand. |

| Reserved | Units reserved by held orders or active carts. |

| Available | Current stock minus reserved stock. |

| Threshold | The configured low stock threshold. |

| Unit Price | The product's selling price. |

| Stock Value | Total value of stock on hand (current stock x unit price). |

Filtering the Low Stock Report

The inventory report has a store type filter to view products by store type (cannabis, general, or both). There are no category, supplier, or severity filters on this report.

Taking Action on Low Stock

When you see items in the low stock report, you have several options:

Reorder from Supplier

- Note the products and quantities needed from the report.

- Navigate to Products page dropdown > Ordering & Transfers > Purchase Orders.

- Create a new PO for the relevant supplier.

- Add the low stock items with the quantities you need.

- See Purchase Orders for the full workflow.

Transfer from Another Store

If another store in your organization has surplus stock:

- Navigate to Products page dropdown > Ordering & Transfers > Stock Transfers.

- Create a transfer request from the store with surplus to your store.

- See Stock Transfers for the full workflow.

Adjust the Threshold

If a product is consistently flagging as low stock but you intentionally keep it at low levels (e.g., a slow-moving specialty item), adjust its threshold:

- Open the product.

- Lower the Low Stock Threshold to a more appropriate level.

- Save.

Ignoring False Positives

Some situations may create false low stock alerts:

- Seasonal items that you intentionally run down before a season ends.

- Discontinuing items that you are selling through without reordering.

- Items on hold waiting for a pricing decision before reordering.

For these cases:

- Set the product's threshold to

0to suppress the alert. - Or deactivate the product if you are discontinuing it entirely.

Low Stock Dashboard Widget

The admin dashboard shows a low stock items count with a link to view them in the full inventory report.

Best Practices

- Set meaningful thresholds. Base thresholds on your actual sales velocity and supplier lead times, not arbitrary numbers.

- Review weekly. Check the inventory report at least weekly, ideally at the start of each business day.

- Use per-product thresholds for key items. Your top sellers deserve customized thresholds that reflect their higher turnover.

- Act promptly. Low stock flags are only useful if you act on them. Create purchase orders as soon as items are flagged.

- Monitor trends. If the same products repeatedly appear as low stock, consider ordering larger quantities or more frequently.

What's Next?

- Purchase Orders -- Create POs to replenish low stock items.

- Stock Transfers -- Transfer surplus stock from another store.

- Stock Adjustments -- Correct stock counts after a physical check.