Purchase Orders

Purchase orders (POs) formalize your requests to suppliers and provide a structured way to receive inventory into your store. When you receive a shipment against a PO, stock levels are updated automatically and the receiving details are recorded for your records.

Purchase Order Workflow

The typical purchase order lifecycle:

Pending --> Confirmed --> Shipped --> Received

--> Cancelled

| Status | Meaning |

|---|---|

| Pending | PO has been placed and is waiting for the supplier to confirm. |

| Confirmed | The supplier has confirmed the order. |

| Shipped | The supplier has shipped the order. |

| Received | All items have been received. Stock has been updated. |

| Cancelled | PO was cancelled before completion. |

Creating a Purchase Order

- Navigate to the Products page dropdown > Ordering & Transfers > Purchase Orders.

- Click New Purchase Order.

Step 1: Select the Supplier

- Choose the Supplier from the dropdown.

- If the supplier does not exist, you will need to create it first via the Products page dropdown > Ordering & Transfers > Suppliers.

- The supplier's contact information is auto-populated on the PO.

Suppliers must be created before you can issue purchase orders. Go to the Products page dropdown > Ordering & Transfers > Suppliers to add suppliers with their name, contact details, and address. See Categories & Brands for supplier setup instructions.

Step 2: Add Line Items

- Click Add Item to add a product to the PO.

- Search for the product by name or SKU.

- If the product has variations, select the specific variation.

- Enter the Order Quantity — how many units you want to order.

- Enter the Unit Cost — the price per unit you expect to pay. This defaults to the product's cost field if set.

- The Line Total calculates automatically (quantity x unit cost).

- Repeat for each product you want to order.

Step 3: Add PO Details

| Field | Required | Description |

|---|---|---|

| PO Number | Auto-generated | A unique identifier for this purchase order. This is auto-generated and not editable. |

| Order Date | Yes | The date the order is placed. Defaults to today. |

| Notes | No | Internal notes or special instructions for the order. |

Step 4: Submit the Order

Click Create Purchase Order. The PO is created with status Pending.

You can:

- Print the PO to hand-deliver or fax to the supplier.

- Download as PDF to email as an attachment.

Brother POS does not send POs to suppliers automatically. You handle delivery of the PO yourself.

Receiving Inventory Against a PO

When a shipment arrives from the supplier:

- Navigate to the Products page dropdown > Ordering & Transfers > Purchase Orders.

- Find the PO (filter by status or search by PO number).

- Click the PO to open it.

- Click Receive Items.

The Receiving View

The receiving view analyzes line items for existing vs new products. It shows which items match existing products in your catalog and which would need to be created as new products.

Receiving the Order

- Review the line items and their product matches.

- For each line item, you can specify the quantity actually received — this may differ from the ordered quantity.

- Items with a received quantity of 0 are skipped (not received).

- Click to receive the order.

Partial receiving is supported. You can receive fewer items than ordered on each line item. The system tracks the quantity received per line and updates stock accordingly.

What Happens on Receipt

- Stock is updated -- The received quantities are added to each product's current stock.

- PO status updates -- The status changes to Received.

- Cost is updated -- If the actual unit cost differs from the PO cost, you can update it during receiving. This updates the product's cost field.

- An audit record is created -- The receiving event is logged with timestamp, user, and quantities.

Managing Purchase Orders

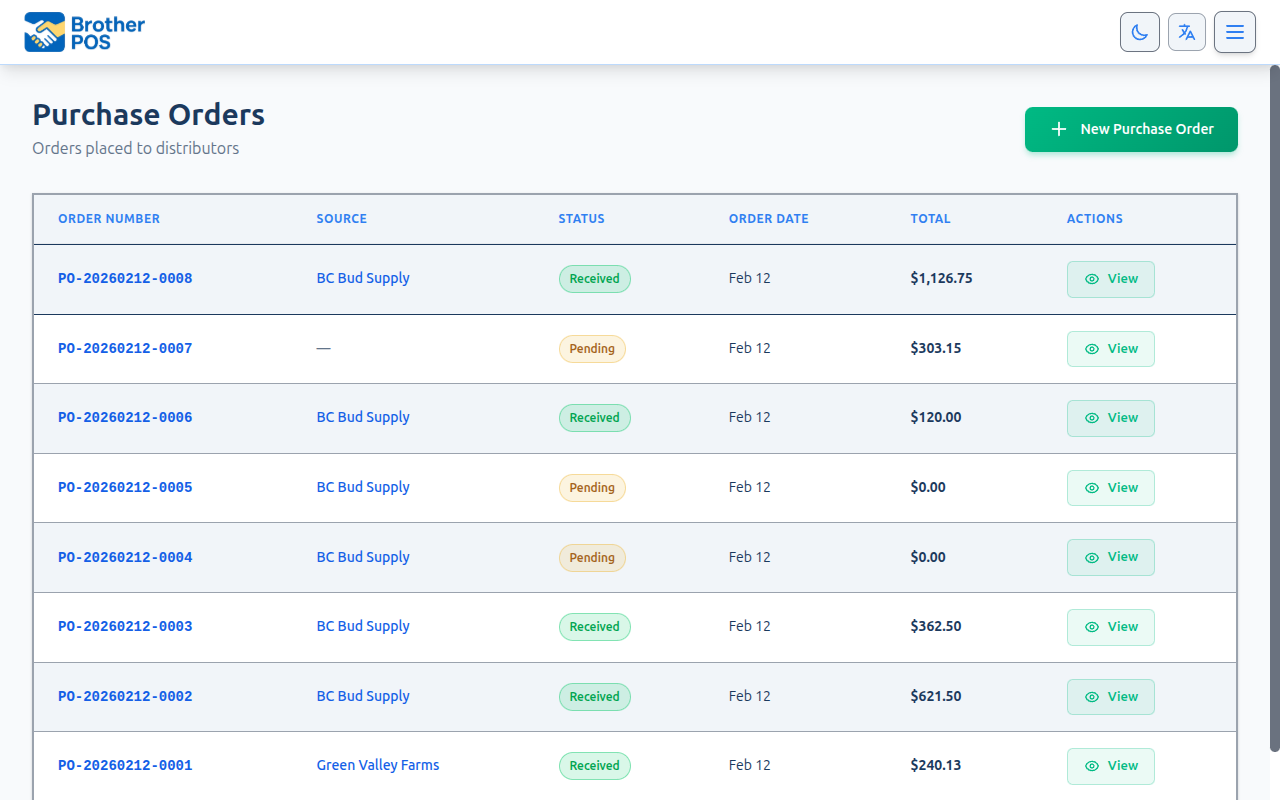

Viewing PO History

- Navigate to the Products page dropdown > Ordering & Transfers > Purchase Orders.

- The PO list shows all purchase orders with their status, supplier, total, and dates.

- Use filters to narrow the list:

- Status — Pending, Confirmed, Shipped, Received, Cancelled.

- Supplier — Filter by a specific supplier.

- Date range — View POs within a specific time period.

Cancelling a PO

If you no longer need the order:

- Open the PO.

- Click Cancel PO.

- Confirm the cancellation.

- The status changes to Cancelled.

If you cancel a PO after receiving some items, the stock already received remains in your inventory. Only future receiving is prevented. You may need to create a stock adjustment if you want to return the received items to the supplier.

Purchase Order Reports

Purchase order data feeds into inventory valuation -- PO costs contribute to your inventory valuation calculations.

Best Practices

- Always use POs for receiving. Avoid manually adjusting stock when receiving supplier shipments. POs create a proper paper trail.

- Verify counts at receiving. Count every item in the shipment. Do not assume the supplier sent the correct quantity.

- Note discrepancies. If the shipment quantity does not match the PO, document it in the receiving notes.

- Review pending POs regularly. Overdue POs (past their expected delivery date but still pending) may indicate a supplier issue.

What's Next?

- Stock Adjustments — Correct stock manually when needed.

- Stock Transfers — Move stock between stores.

- Low Stock Alerts — Get notified when it is time to reorder.

- Categories & Brands — Set up suppliers before creating POs.